Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

How to comply to the OSHA HazCom 2012 Standard

The Globally Harmonized System (GHS) is an international system that the United Nations created for the unified classification and labeling of chemicals. It was officially adopted in the U.S. on March 26, 2012 by the Occupational Safety and Health Administration (OSHA). OSHA's adoption of the GHS is actually a revision of the Hazard Communication Standard designed to align with the GHS. It's called HazCom 2012.

A written HazCom plan that documents and outlines how your company responds to hazardous chemicals is required in order to comply with OSHA's 29 CFR 1910.1200(e) regulation for Hazard Communication. Tracking, maintaining and managing your chemical inventory is crucial to your HazCom plan and GHS compliance. In order to maintain a successful plan, you must keep your inventory organized and updated.

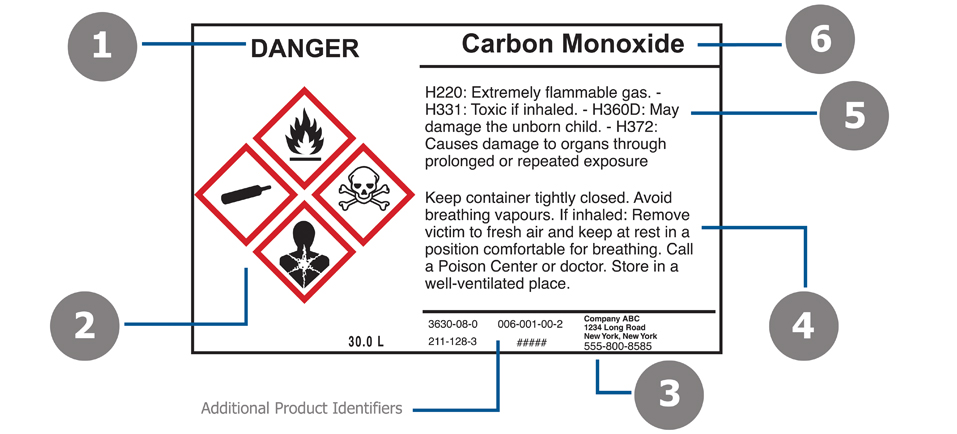

Labeling is the cornerstone of GHS compliance. With an emphasis on consistency and comprehension of chemical labels, it is important to know what goes into a GHS compliant label for primary and secondary containers. There are six key GHS label elements that you need to know.

The signal word indicates hazard level. "Danger" is used for the most severe instances, while "Warning" is less severe. View our GHS Signal Words guide.

These pictograms are used to identify hazardous products and are commonly grouped by chemical / physical risk, health risk and environmental risk. View our GHS pictogram guide.

This identifies the manufacturer's company name, address and telephone number.

These are phrases that are tied to each hazard statement. They describe general preventive, response, storage or disposal precautions. These statements are found on the chemical's Safety Data Sheet. Similar to Hazard Statements, Precautionary Statements can be identified by a P-Code (like P100).

These are phrases that describe the nature of hazardous products and the degree of hazard. Hazard statements are on the chemical's Safety Data Sheet (SDS) and identified by an H-Code (like H100). View our GHS Hazard Statements guide.

This identifies the product or chemical name. Additional identifiers can be noted to the right of the Manufacturer's information (#1).

Primary chemical containers are the bags, barrels, bottles, boxes, cans, cylinders and drums that you receive from the manufacturer. These containers should be labeled following the GHS mandates per the GHS label example above and include all six labeling elements.

When a label is on a container directly from a supplier, this label cannot be removed, altered or defaced. If it needs to be replaced, the new label must contain the same information as the original.

Secondary containers are usually smaller than primary containers and could include spray bottles, jugs or jars. These containers usually hold chemicals that are transferred from a primary container. GHS labels for secondary containers must comply with labeling requirements except when the following criteria are met:

OSHA has not changed the general requirements for secondary container labeling specifically. Employers have the option to create their own workplace labels by using all of the information provided by the manufacturer or using a combination of the label elements, specific to the hazards of the chemicals, from the above GHS label example.

Employers may continue to use rating systems such as the National Fire Protection Association (NFPA) diamonds or Hazardous Materials Identification System (HMIS) requirements for workplace labels, as long as they are consistent with the HazCom 2012 / GHS standard.

As with most things, knowing is only half the battle. Now that you know the GHS Label Requirements, it's time to put them into practice. Proper training on the GHS labeling requirements is highly recommended so that both the employer and employee can align to ensure compliance.

Further reading: OSHA's 29 CFR 1910.1200(e) regulation for Hazard Communication

Since the implementation of the GHS in 2012, we've been collecting frequently asked questions from our customers and during our webinars. Our experts have answered the most commonly asked questions and put them all in one place.