Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Bridging the gap between physical and digital capabilities in manufacturing environments creates a significant competitive advantage. Among the benefits: increased agility and flexibility, lower costs, less downtime, better productivity and faster, smarter decisions. This convergence will displace companies that don’t embrace it, and many are behind. Their manufacturing operations still exist in two completely separate worlds: the traditional, physical world of operational technology (OT) and the data-driven world of digital technology (IT). While there are challenges that must be overcome to bring the two together, the risk of not doing so is quite real — especially when competitors are making the leap.

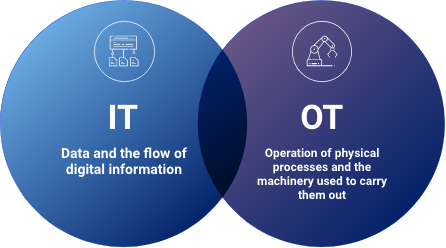

Simply put, IT/OT convergence is the integration of IT systems with OT systems. It is central to today’s intelligent manufacturing and industrial IoT initiatives. To best understand bringing these two systems together, it’s important to first understand the core parts of each system.

Traditionally, IT and OT systems have operated in separate spheres. Today, however, the rapid proliferation of connected “things” (IIoT) has increased the appetite for real-time data and analysis exponentially. Innovations in edge computing, artificial intelligence, machine learning and machine-to-machine communications continue to advance what’s possible. Keeping IT and OT separate puts a business at a disadvantage by limiting a company’s ability to:

Companies must now execute effectively on the priorities they have laid out in the areas of remote operational capabilities, data-driven decision making, and resiliency across their technology and operational capabilities to support volatile market dynamics.”

Jonathan Lang

Research manager, Worldwide IT/OT Convergence Strategies at IDC1

Integrating IT and OT into a seamless, holistic system that encompasses production and business functions gives companies access to real-time, actionable data and analytics organization-wide, enabling them to:

Successful IT/OT convergence requires companies to be deliberate about education, cross-training and collaboration. Each side needs to be well-versed in the day-to-day activities, needs, challenges and risks of the other, and they have to work together productively to benefit the organization as a whole. Shared responsibility, defined processes, clear KPIs and a commitment to open communication will enable teams to clearly assess and successfully overcome IT/OT convergence challenges. Here are some of the most-often encountered IT/OT convergence challenges and a few ways to solve for them.

| Challenge | Issue | Solution |

| Legacy equipment | The lifetime of IT equipment is generally 3-5 years. Industrial equipment can still be in good shape decades after deployment — with decades-old technology on board. | Layer an IT data exchange system on top of an OT system to gather and process data without having to make modifications to existing operations hardware. |

| Device capabilities | Some edge devices may not be as adept at receiving and acting upon incoming data as they are at generating and sending it. | Engage an experienced applications developer, because customized applications will always be necessary for effective edge computing. |

| Compatibility | A lack of shared standards or protocols may inhibit the ability of IT and OT systems to work symbiotically. | Choose hardware and software suppliers that support a wide variety of industrial protocols, standard APIs and modern IIoT protocols such as MQTT. |

| IT systems capacity | All that data streaming from industrial machines and other edge devices has to be ingested, stored, analyzed and distributed to be of any use. | Identify and engage an operations and an IT lead early on. Cooperation is essential when deciding how data will be managed. |

| Scalability | Manufacturing often has to turn on a dime to accommodate changing customer needs, supply chain problems, vendor issues, etc. | Establish clear expectations and accountability with everyone who will be affected by a change. Implement processes to get the right information to the right people at the right time. |

| Security | Anything connected to the internet becomes fair game for a debilitating cyberattack, and more "things" = a greater attack surface. | Reduce the number of vulnerabilites a hacker can exploit by creating strong boundaries between business and process control networks. Deploy mesh cybersecurity architectures to secure individual devices. |

| Redundancy/failover | Critical operations cannot afford to deal with IT system outages. "Five-nines" uptime — 99.999% — is essential. | Design redundancy into data exchange systems. Reliable, resilient hybrid edge/cloud architectures enable fallback data exchange and processing at the edge or in the cloud. |

| Skills gap | Many organizations lack the skills or expertise to successfully integrate their IT and OT systems. | Engage an experienced systems integrator to work side by side with a manufacturing engineer to design the data exchange and analytics system. Use no-code or low-code applications to empower more people. |

Interconnectivity and data analytics aren’t just nice to have — they have the power to revolutionize your operations. Modernizing your manufacturing operations through IT/OT convergence doesn’t have to break the bank. For more than a century, Brady has worked side by side with our customers to solve tough manufacturing challenges and design for what comes next. With a specific focus on manufacturing, we design industrial data exchange ecosystems. We can help you connect business and process systems for:

Let’s have a conversation to discuss what a flexible manufacturing environment can do for you.

You will receive a response within 1 business day.