Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Electricity powers the world. It lights up, turns on and charges nearly everything we touch, all with the flick of a switch. But behind switch plates and outlets lies a colorful, spaghetti-like network of wires: red, black, yellow, green — each designed to connect, and keep us safe.

Whether you install, repair or upgrade wires, you may have noticed, no two wiring systems are exactly the same. But most do share at least one thing in common: a way to identify each wire. And that way is with color.

Simply put, color makes it easier to work with wires. Just ask those who come in frequent contact with wires, mainly:

Instead of wondering … Is this wire hot? Neutral? For grounding? A quick look at a wire’s color can reveal its role in powering an appliance or circuit. It’s simple. It’s safe. And, it’s designed to take the guesswork out of electrical work.

But it wasn’t always this way.

It took until 1928 for wire color coding to make its debut. The National Electrical Code® (NEC) was the first to reference it, and today continues to set the standards for the electrical industry. Following a uniform color code makes it easier to assess electrical wiring, and ensure safety among licensed professionals and homeowners alike.

Color has many benefits, especially when used with electrical wires.

It’s no mystery, color gets our attention. When compared to non-colored items, it’s the colored ones that command more of our visual attention. For electricians, wire colors indicate how power moves within circuits.

Color alerts us to danger. In the case of electricity, recognizing a red electrical wire (hot wire) could mean lowering the risk of electrical shocks, burns, electrocution and fires. If a body encounters a high-magnitude electrical surge, it could take years to recover.

“You can’t tell just by looking at a patient what some of the complex, life-altering effects of electrical injuries are.”

-John Cho, occupational therapist and clinical coordinator for the outpatient Back on Track rehab program at St. John’s Rehab Hospital.[1]

Prevention, therefore, is key when it comes to electrical safety. And color can help reduce the overall risks.

We remember better when colors are used compared to when they’re not. That’s because colors play an essential role in keeping information in the memory system. Since electrical wires are colored, it’s easier to understand their purpose within a network.

Whether in a commercial, residential or industrial setting, incorrectly identifying wires could lead to accidental outages, causing unexpected downtime for both residents and workers. Colored wires prevent outages by creating a reliable system of identification.

Repairs are expensive when a wrong wire is cut. Power outages can cause missed transactions and lost sales. Using colored wires could end up saving businesses money in the long run.

Electrical incidences such as overheated wires or fires can cause significant property damage. Using colored wires can lower this risk by ensuring circuits are connected properly.

Though there are international wire color codes, the U.S. follows the National Electrical Code® (NEC). The code is identified as NFPA 70® because the NEC is sponsored by the National Fire Protection Association. Though not a federal law (states can choose to adopt it), it is approved by the American National Standards Institute (ANSI). Every three years, the NEC reviews, amends and adopts the latest code. The current NEC was last updated in 2020. Make sure to stay up to date with these different changes to cable labeling standards to keep you and your team safe.

Most businesses adhere to the NEC because it’s state law. Others follow it because it’s considered a best practice for improving workplace safety. Injuries and incidents may be costly, so wiring, regardless of its scope or scale, should be taken seriously.

In addition to making new installations safer, following the NEC provides communication for future projects. Workers, maintenance crews and contractors (who frequently update wires) have come to rely on this color-coding system. It makes troubleshooting easier, and faster.

If you’d like to become a licensed electrician, your training will require a solid understanding of the NEC. This ensures consistency, whether on new construction or if updating wiring in a pre-existing building.

There is no extra cost for following the wire coding standards. The thin, PVC sheath that wraps each wire costs the same for each color.

These benefits encourage businesses to accept practices that have been adopted in their area.

The wire color coding guidance provided below applies to electrical wiring in the United States. Though there may be exceptions (e.g., old wiring, regional differences, the wrong color wire was installed), this section can be used as a general overview for electrical wire color codes.

In addition to identifying a wire by its color, always check to see that wires are de-energized. Of major concern are hot wires, which carry live electrical current from the electrical panel to outlets and light fixtures.

|

Black wiresIndicate a hot wire, one that carries electricity. You will need to shut off the circuit breaker before working with these wires. They go from a power source (breaker panel) to electrical outlets and switches, and connect wall switches to fans, lights, appliances and machinery. |

|

Red wiresIndicate a secondary hot wire, one that carries electricity. You will need to shut off the circuit breaker before working with these wires. They can be used to interconnect smoke detectors, power wall switches for ceiling fan lights, and to power outlets for a 240-volt appliance like an air conditioner, electric water heater, stove or dryer. |

|

White wires with black or red tapeIndicate a hot wire, one that carries electricity. You will need to shut off the circuit breaker before working with these wires. When you see a modified white wire (with black or red tape wrapped around it), it signals the wire is hot, not neutral. You may see these in 240-volt outlets replacing the red wire as the second live wire. |

|

Copper wiresIndicate a ground wire. These wires provide a path for an electrical current if a device shorts out or trips a breaker. These bare wires connect to outlets, switches and metal appliance frames and pass the current to the ground. |

|

Green wires or Green with a Yellow Stripe wiresIndicate a ground wire. These wires reduce electrical overload (which could cause fires) by redirecting excessive electricity. They ground the electrical circuit by connecting to a grounding terminal in an outlet box and connecting to a metallic strip (busbar) in an electrical panel. |

|

White wires or Gray wiresIndicate a neutral wire. These wires carry electricity back to the breaker box. They essentially return power from a hot wire back to a grounded portion of an electrical panel to complete the circuit. |

|

Blue wires and Yellow wiresIndicate a hot wire. These are usually found in a conduit for plug-in electrical devices. Known as travelers, blue and yellow wires allow operation of an appliance or lights from multiple locations. |

Whether adding a home appliance or industrial machinery, you’ll need to know these electrical wiring color codes. In the U.S., these color-coded wires carry power from a circuit breaker to a device.

Alternating current (AC) is the power that comes out of outlets in homes and businesses.

Homes and offices: 120, 208 or 240 Volts

Industrial equipment: 277 or 480 Volts

When powering higher-voltage devices, be sure you are labeling wires and cables accurately and add safety signs, where needed. This identification can be used during a lockout tagout, should the equipment need to be de-energized.

Direct current (DC) is used in cell phones, flashlights, cars and solar panels. It can also be used for industrial processes and to transmit large amounts of power from remote locations.

Just like no two electrical projects are the same, you’ll find Brady support comes in different shapes and sizes. We offer industrial label printers, cable labels, wire markers, heat shrink sleeves, electrical safety signs and software — effective and easy ways to communicate vital information, and stay safe.

Portable label printers offer the ultimate blend of convenience and durability, and Brady carries a full lineup. Bluetooth wire label printers, like the BradyPrinter M611 Mobile Label Printer and the M211 Label Printer, allow you to design, preview and print labels using a phone’s familiar keyboard and an app. The M210 Handheld Label Maker, on the other hand, lets users design, create and print labels using a traditional built-in printer keypad. Find out how to select the right wire marker for you from our guide.

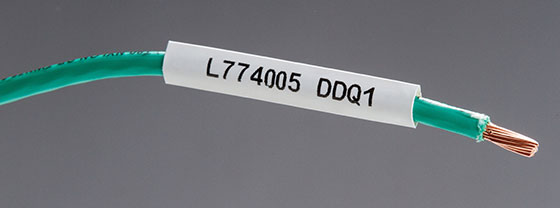

In addition to color ID, we offer high-performing wire and cable labeling materials that can keep you compliant. Some are self-extinguishing, while others resist chemicals, oil and moisture. In flags, tags, self-laminating, rotating and wrap-arounds, Brady wire markers and cable labels are durable and designed to stay visible in any environment.

Brady also makes pre-printed and custom tags and safety signs. These can also be created with on-demand label printers. Informing others about potential electrical hazards (conduit labels, voltage markers, electrical panels, arc flash, lockout tagout) can reduce the threat of injury. Whether posting indoors or outdoors, just know the text, graphics and color will hold up to the elements, abrasion and repeated spills and cleanings.

If you’re looking for additional solutions, we’re here to help. Let us know a little more about your application and we’ll gladly recommend products and services that can improve your work experience.

References

Learn how to get real value by using the right labels with this guide on labeling wires and cables

Learn More

Your full start-to-finish solution to your Information and Communications Technology (ICT) identification needs

DOWNLOAD

Need to see a sample of our wire and cable marking labels? Request a free sample pack here.

Request a SampleComplete our short form and one of our representatives will contact you.