Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

In 2020 alone, the Bureau of Labor Statistics (BLS) reported that there were more than 2.7 million nonfatal workplace injuries and illnesses. Pretty sobering statistics. When you’re running your own business or responsible for the safety of your employees, decreasing and eliminating safety risks is undoubtedly on the top of a very long list of responsibilities. One easy-to-execute effort is adding effective signs and symbols to your workplace. They can help prevent accidents and keep your biggest asset — your people — safe.

A visual workplace is a key element in a safe workplace. When things are visual in your facility, employees can easily glance at a sign and immediately know what it means. There’s no need to translate or make employees guess at the meaning. In conjunction with thorough safety education and personal protective equipment, all workers can be well prepared to do their work as safely as possible.

With what’s at stake related to safety at your workplace, it’s important to know the why, what and how behind safety signs and symbols to combat optimism bias and protect your employees. That way, anyone who interacts with your organization knows what hazards to look out for and how to protect themselves when entering your workplace.

Per the Occupational Safety and Health Administration (OSHA), safety signs are used to “define specific hazards that could harm workers or the public, or both, or cause property damage.” In other words, all signs share the common purpose of communicating safety messages for a variety of purposes — from employee training to safety equipment.

Some signs — such as hazardous materials signs — warn people about serious dangers that are present in the area. Other signs — such as floor obstacle signs — caution against minor risks. In certain cases, signs can simply be used to provide instructions and proper procedures.

Your use of signs will vary depending on your workplace risks. For example, organizations that deal with a lot of electrical equipment should focus on providing protection against those specific hazards. This means adhering to all lockout tagout best practices, which include using signs to warn people, as well as installing circuit breaker lockout devices to minimize the physical dangers to employees.

In addition to general safety signs, OSHA created nine symbols related to chemical safety. These symbols are standardized — always on a white background with a black pictograph and red border. These critically important safety signs warn people about common chemical hazards they may encounter in the workplace, including:

Corrosion: The corrosion sign features two test tubes pouring out a liquid that appears damaging, one above a surface and the other above a human hand. It warns against the potential damage that corrosive substances, such as certain acids, can cause.

Environment: The environment sign depicts a barren tree and a fish that has washed up on land. It warns against chemicals and substances that may be harmful to aquatic environments. This is the only OSHA chemical safety sign that isn’t mandatory.

Exclamation mark: A large exclamation mark, this sign warns of things that may be irritating, particularly to the skin, eyes or respiratory system. This mainly includes chemicals and substances, like adhesives and skin sensitizers.

Exploding bomb: Showcasing a bomb in the process of exploding, this sign signifies the presence of explosive or self-reacting substances.

Flame: This sign features an open flame. It’s used to indicate flammable materials, including self-reacting substances and substances that give off flammable gas.

Flame over circle: The image of the flame sitting on top of a circle is used for oxidizing substances or substances that give off oxygen or other flammable materials. If these substances get too close to reactive chemicals or an ignition source, they could create fire or an explosion.

Gas cylinder: A gas cylinder sign indicates that gas is being stored under pressure. When stored in this manner, gases may be reactive, explosive or otherwise harmful if heated or disturbed.

Health hazard: The health hazard symbol is a silhouette of a human torso with white markings covering the chest. This sign alerts people to chemicals and materials that are harmful to human health, particularly carcinogens.

Skull and crossbones: The skull and crossbones sign exhibits the extreme dangers of being exposed to an acutely toxic substance or a substance that can make you sick, even fatally so, after a single exposure.

Depending on the nature of your work, you may be required to display one or all of these signs to be OSHA-compliant. However, there are also plenty of other signs outside of OSHA that you’ll be required to display as well.

In their specifications for accident prevention signs and tags, OSHA recognizes multiple types of safety signs. Following recommendations from the American National Standards Institute (ANSI), they also outline how to use these signs properly. This means all signs must use the same design features, wording, positioning and colors to ensure worker safety and meet the necessary standards.

These safety signs are required to have clear writing that is easy to read and understand. They should use rounded edges and be fastened or posted in a way that does not pose any further hazards. Signs should be used only for as long as necessary and removed once the hazard is no longer present.

Using ANSI’s standards, OSHA has created unique requirements for each type of recognized safety sign:

Danger signs are used to warn people of “immediate danger” in the workplace and take whatever precautions are necessary. These signs are reserved for the most severe hazards in the workplace, such as warning against radiation or high electrical voltage.

Danger signs must be red on the top panel, white on the lower panel, and black around the borders. The word “DANGER” must be prominently featured in the top panel.

Caution signs are used to alert employees to more moderate risks, such as a slippery floor or an employees-only area. They may point out potential hazards or provide steps to avoid hazards.

Typically, caution signs have a yellow background with black text. They may also use yellow lettering surrounded by a black panel. No matter which style you choose, the sign must read “CAUTION” near the top. A safety message or symbol may follow.

In certain circumstances, you may be able to use a warning tag instead of a caution sign. A warning tag exhibits the level of hazard — more hazard than a caution sign but less than a danger sign. These tags should read “WARNING,” followed by a message describing what the sign is warning against.

OSHA requires organizations to display exit signs throughout the workplace — including at exit doors, the intersection of hallways, and stairways — to signify where entrances and exits are located. Not only is this helpful for people finding their way around the workspace, but it could mean the difference between life and death during an emergency.

Exit signs are usually white and red or green, though certain municipalities may permit you to use other colors. The background may be white with red or green lettering, or the inverse. At a minimum, the letters must be six inches high and three-quarters of an inch wide. The more exit signs the better so feel free to provide additional messaging to stimulate proper navigation.

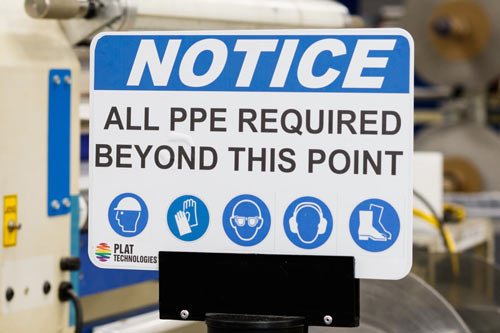

Instead of warning employees about potential hazards, instructional signs provide information. They may remind workers about proper procedures or policies they must follow, such as when operating machinery or wearing personal protective equipment.

Unlike some of the previously mentioned signs, instructional signs don’t indicate serious risk. Thus, a danger or caution sign may be unnecessary in these circumstances. Still, workers need to follow these instructions to stay safe and healthy. There could be negative consequences if they fail to do so.

Depending on where you work, you may also need to display signs to control traffic and parking. These signs may designate where drivers can park, indicate where pedestrians can safely walk or remind people about the rules of the road (such as the stop signs). These signs help protect everyone who comes near your workplace or job site, including employees and passersby.

Accident prevention tags are used only for temporary hazards. They’re most commonly used to indicate that equipment is broken, out of service or due for repairs. Use a tag only when there is no permanent or specific sign available.

Safety signs and symbols clearly play a major role in a safe workplace. They work in conjunction to keep employees safe. And since there are many different kinds — and varied situations that dictate what sign and / or symbol is required — digging into the details is important to ensure you’re accommodating the safest situation. Beyond signs that are required, you’ll likely have a temporary need or two that describes a situation or environment in your workplace that employees need to be aware of. In both cases, signs and symbols are an easy-to-implement element of making safety a priority and feeling good about sending your employees home safely at the end of the work day.

Create a safer, more efficient workplace through visuals.

Learn More

Understand the types, requirements and use for workplace safety signs and symbols.

Learn More