Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Welcome to Ask the Expert with Brady! We recently sat down with Lean expert Klaus Blache to discuss the resurgence of Lean manufacturing and how it can help businesses become more efficient and profitable. Dr. Blache recently led a training session with Brady salespeople to cover Lean terminology and visual control, where the discipline has been and where it’s going, and how to best implement Lean practices in a variety of industries.

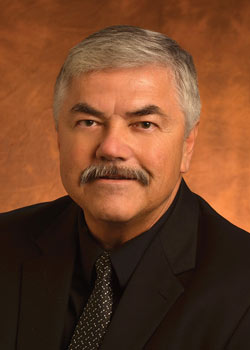

Klaus Blache, PhD

Director of the Reliability and Maintainability Center; Professor

The University of Tennessee

Dr. Klaus Blache is a leading authority on reliability and maintainability. His work as an industry consultant along with the work of his students through the University of Tennessee, Knoxville Reliability and Maintainability Center, with over a dozen training partners, helps businesses develop strategies to instill best practices, reduce costs, and maintain or improve operations and culture. He has extensive experience in the fields of engineering, manufacturing and large-change efforts, and has held a variety of positions in industry. His work at General Motors (GM) included designing new production facilities and heading up its Mfg. Reliability & Maintenance for North America. In addition, he designed and ran an automotive assembly plant as Mfg. Engineering Director, Cadillacs that received the J.D. Power Gold Award for Quality and Most Productive Luxury Car Plant in North America. Other accolades include GM Research’s Most Valuable Colleague Award; GM Chairman’s Award – Lean Implementation; GM Award of Excellence – Maintenance Management; GM Institute Alumni Engineering Excellence Award; and Fellow – International Society of Engineering Asset Management. He also helped initiate and was a two-year Chairman of the Society of Maintenance and Reliability Professionals (SMRP).

Companies understand how much good processes impact success. And those that didn’t definitely began to understand it during the COVID-19 pandemic. They’re beginning to understand how a stable process, with an adaptive mindset workforce, can save money but also get time and resources back in the face of labor shortages and supply chain issues. Lean manufacturing is being better intertwined with other concepts like reliability and maintenance. Also, during all these supply chain shortages, stability in processes is more dependable than just-in-time delivery. An engaged workforce helps you adapt to be successful.

Start from the beginning - learn the fundamentals of Lean Manufacturing here.

The facilities that say they don't have time to implement Lean manufacturing and proactive maintenance somehow always have time to perform reactive maintenance, which in turn costs five to 10 times as much. What they're really saying is that Lean is not a priority, not that they don’t have the time. Lean is a process, and you just need to take it one step at a time. Start with the basics like 5S and Standard Work. That will tell you if you have a culture of discipline and buy-in necessary for continuous improvement. If you implement without it, expect to give up half of the potential Lean savings.

Learn more about implementing Lean / 5S and how to get started.

It’s always about the dollars (show me the money!). Start by demonstrating the potential savings and return on investment that’s possible with Lean processes. Conduct assessments (on foundational elements of R&M) and a gap analysis to identify areas where improvements can be made. Start small and implement process improvements in a pilot area. If you can show success and returns there, you can make your case to expand the program.

Need some tips on how to implement Lean manufacturing? Check out this article on Managing Change.

Only three? That’s tough but I’d say you need to start by engaging the workforce. Then, reinforce those improvements over time. You do this not just by telling people to do something, but by getting out there, explaining things and coaching back to standardized work. When employees understand the purpose and value of their work, they are more likely to be invested in the process. Finally, visual controls are key to making process improvements sustainable and repeatable.

Get the team involved in the process. This would most likely be done via a Kaizen, 5S or other continuous improvement event. People don’t resist change, they resist how it’s done to them. You can take this uncomplicated step and make it collaborative. If workers are part of that, they’re more likely to feel accountable and invested. Again, it comes back to that culture of Lean/R&M discipline. Once they feel that they have some control over improving their work area with simple changes, they will be more willing to take on more complicated tasks.

I mean, where do I start? Visual controls are essential for sustaining 5S and implementing error-proofing and mistake-proofing. They’re used throughout the TPM (Total Productive Maintenance) process: equipment inspections, machine maintenance, lubrication points, quality control checks, you name it. A good visual control can give you the information just for knowledge, or alert you to make a decision if something is wrong or an abnormality is made visible.

This guide outlines how to create a safer, more efficient facility with visuals.

Faster and better. When a company has good, logical processes and visual controls, employees do things in a logical way. It also shortens the learning curve for new employees as well.

TPM is the umbrella over standardized work. TPM is a comprehensive process that includes everything in the maintenance spectrum, while standardized work is just one small piece of the puzzle. Standardized work helps make work repeatable, while TPM covers all aspects of maintenance, including team building and developing a proactive maintenance culture.

Learn more about how to improve equipment performance and reliability with TPM.

Absolutely. Typically, the more reactive you are, the more your workers are put at risk. It’s just logical. More emergencies and quicker repairs put more people at risk. A reliable plant is a safe and cost-effective plant. And a reliable plant comes from a culture of employee discipline. When people are accountable and following standardized work, they’re also reliable. Reliability of process and product is great. But you also need to have reliability of people. Without it, you don’t have sustainable reliability of an overall plant floor process.

Incentive? No/not sure. Should they? Yes. In a perfect world, the skilled trades would be part of the manufacturing process, because they know what they’re going to need to find and fix. A good example would be to pre-label all the lubrication points on a piece of machinery. But now, you’re building in an additional cost for the OEM. But flip that around, it could be a competitive advantage, because here’s a product that can get fixed faster. I don’t think we’re there though.