Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

If your industry is like most, you need to keep track of products and assets. Barcodes can be a great solution, but did you know there are different types of barcodes that best serve different applications? Both 1D and 2d barcodes are essential to trade and supply chains, plus work to ensure:

Simply stated, a barcode represents product or asset data in a visual form. It often contains information about the item’s price, where and when it was manufactured, plus it identifies the business that made it. Once a barcode is read by a scanning device, it provides a quick and accurate way to track assets and in-process products, plus monitor inventory.

Two types of barcodes are one-dimensional (1D) and two-dimensional (2D). Both are effective, but differ in application, scanning technology, layout and amount of data that can be stored. Your work usually determines which type you’ll use, and likewise, the type of technology you’ll need: printers, scanners, readers and software.

A one-dimensional (1D) barcode (also known as a linear barcode) is an image with vertical lines and spaces that vary in width. Within those lines and spaces, data is encoded from left to right in a horizontal line. This type of barcode holds up to 85 characters. More data means more characters are needed.

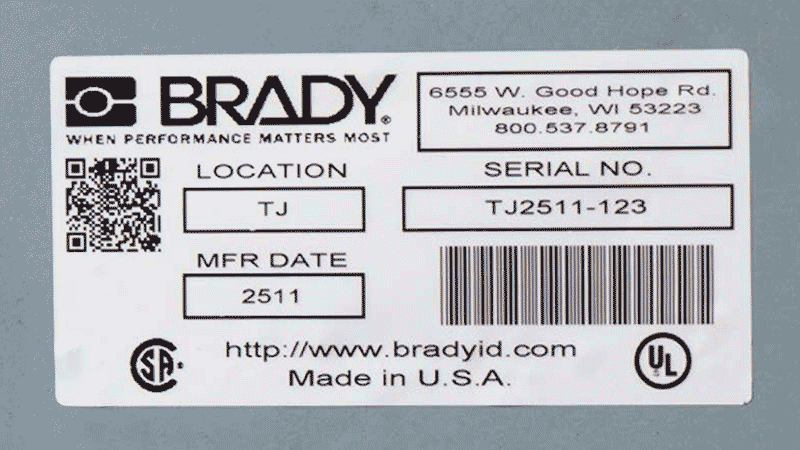

The most recognizable example of a 1D barcode is a Universal Product Code (UPC) found on grocery and consumer items. It contains a barcode and 12-digit number (the first 6 being the manufacturer’s ID number, the next 5 are specific to the item, and the final digit confirms the integrity of the code).

A two-dimensional (2D) barcode is an image with dots, squares, rectangles and hexagons. These barcodes store data vertically and horizontally. Information like web addresses, text, images and coupons are encrypted in camera-readable formats. This type of barcode holds up to 7,089 characters.

A QR code (quick response code) is a common type of 2D barcode. These popular, scannable squares can be read by lasers or mobile phones.

Like their name implies, QR codes allow users to access information instantly. Common uses include tracking products or assets in a supply chain and marketing campaigns.

Barcodes have not always been with us. In fact, the first use of the linear barcode dates back to 1960, to identify train cars. As laser technology developed, so did linear barcodes. In 1974, the UPC code made its debut when a package of Wrigley’s gum sold in Marsh’s Supermarket in Troy, Ohio.

In 1994, the 2D QR code was developed by Denso Wave, a Toyota subsidiary, to track vehicles during the manufacturing process. Now, QR codes identify products and tickets, allow payments and connect you to a myriad of digital destinations like Facebook, maps, phone numbers and even a patient’s medical information.

Sometimes companies use many different barcodes in their applications. If you’ve made a recent purchase, you may have noticed your item (and its package) feature both 1D and 2D barcodes. That’s because different types of barcodes are used for different functions.

A big difference between 1D and 2D barcodes is the device that’s used to read them.1D barcodes are read with a laser barcode scanner. 2D barcodes require a 2D imager. Other factors that determine barcode type include supply chain requirements and industry-specific applications where a certain barcode type is preferred.

Understanding the full range of what 1D and 2D barcodes can do, plus their limitations, will help you choose what’s best for your operations.

This type of barcode is suited well for applications where information changes frequently, like weekly specials in a grocery store. 1D barcodes are widely used in retail where we see price changes, promotions and limited-time offers. The barcode (static data) lets the person at the register know what a product is. Then, the register adjusts the price based on a pricing database (dynamic data), and removes it from inventory.

Since 1D barcodes have a limited amount of information that can be stored within each barcode, they need to be linked to an external database. The scanner provides the link to an external database with more information. For businesses, the combined use of barcodes, scanners and databases improves inventory accuracy, plus saves time.

1D barcodes are also known for holding up well in industrial environments. Even a heavily damaged barcode can be read and decoded if the scanner can pass through the lines and spaces. These barcode labels are the perfect tool to track products, components, lab specimens and industrial equipment.

This type of barcode is excellent for applications that use detailed tracking information that doesn’t change. This includes everything from smaller surgical instruments to electronic printed circuit boards. Examples of 2D barcodes include:

Scannable squares read by lasers or mobile phones. Common uses include tracking products or assets in a supply chain and marketing campaigns.

A scannable code that consists of 4 bars and spaces in a pattern that is 17 units long. Used for a variety of applications like ID cards, inventory and transporting goods.

Scannable black and white cells arranged in square and rectangular patterns. These codes are used for tracking printed media, inventory and keeping track of ‘sell by’ dates on foods.

2D barcodes are gaining popularity in industrial manufacturing and supply chains. They contain embedded URLs so they can unlock the full capabilities of connectivity. For example, scan the QR code below. It connects you with an Intelligent Manufacturing web page devoted to interconnectivity.

Try it yourself! Use your phone camera to scan this QR code.

Other 2D barcode benefits include:

Tip: If you’re looking for barcodes that stand up to tough, industrial environments or out in the field, choose QR codes. Even if they are stained with dirt and oil, they can still be read.

Both 1D and 2D barcode labels can modernize your manufacturing. So can RFID tags and readers. The difference between 1D, 2D and RFID tags is that RFID tags are sensed automatically when they get within a certain range, which saves time and labor. This differs from 1D and 2D barcodes that sit on a product’s surface and need to be scanned.

So, still wondering which barcode is the best? It’ll be the one that serves your needs.

First, consider all the factors. Your industry or supply chain may dictate the barcodes you’ll use, or the people with whom you do business. Maybe the item you need to identify is small, difficult to scan, or has a lot of information. In that case, use 2D barcode labels. Also, keep in mind that certain applications have strict identification requirements or compliance that needs to be met. The bottom line: use barcodes that fit your type of work.

1D and 2D barcodes can help you realize your business goals. They save time, money and a ton of unnecessary labor. With more accurate inventory and tracking, you can continue to grow and modernize. Both essential elements to compete in today’s marketplace.