Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

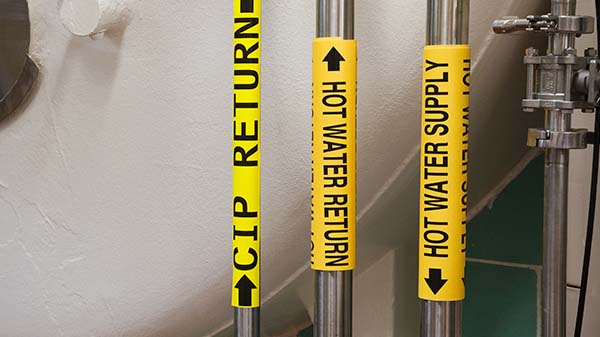

Keeping track of products, components, inventory and equipment is essential. Just ask someone who has wasted time trying to locate an item. An easy way to avoid uncertainty? Use a barcode. Far from the simple images they appear to be, barcodes are powerful tools that transform the way work gets done. For businesses looking to modernize, an intelligent solution like barcode labeling is key to:

And that’s just the beginning. Barcodes help you understand industrial flow – where items are going and where they’ve been. But, most of all, barcodes add visibility to industrial processes.

Using barcodes is easier than you think. With high-performance printing systems, materials, scanners and software, you can build an intelligent solution that fits your workplace. Start by focusing on areas that are important to your business such as:

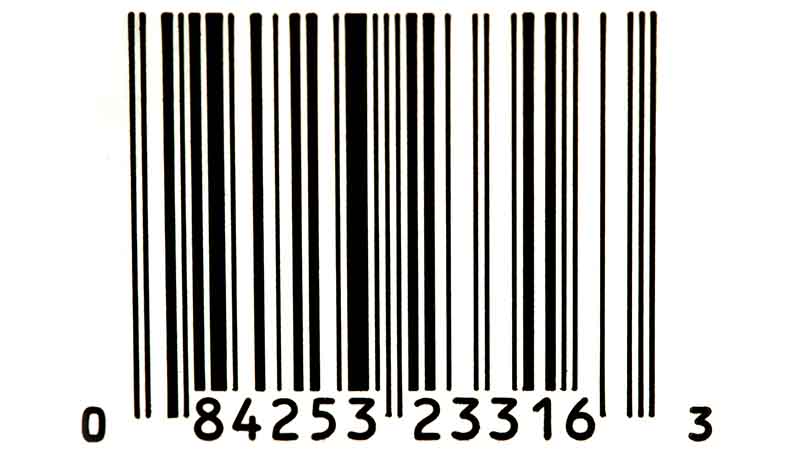

Barcodes are everywhere. They work well in manufacturing environments and in labs to identify samples, equipment and components. Two different types of barcodes used for tracking are one-dimensional (1D) and two-dimensional (2D). Which one you use depends largely on your work.

An image with vertical lines and spaces

Capacity: Holds up to 85 characters (manufacturer and product info)

Example: UPC Code (Universal Product Code)

Common uses: Track products, components, lab specimens, industrial equipment

An image with dots, squares, rectangles and hexagons

Capacity: Holds up to 7,089 characters (web addresses, images, coupons)

Example: QR Code (Quick Response Code)

Common uses: Track components, electronic printed circuit boards, surgical instruments

Though 1D barcodes are widespread, 2D barcodes are gaining popularity in industrial manufacturing and supply chains. They can embed a URL and link the user to far more information than can be stored on the label itself.

If you’re wondering about barcode standards, many industries have them, from pharmaceuticals to packaging. By far, the most common barcode standard in the United States is the UPC barcode, or Universal Product Code. It’s found on almost every retail and grocery store item.

A UPC barcode consists of 12 digits: the first six identify the manufacturer and the next six digits are the item number. The final digit confirms the integrity of the barcode.

Sometimes barcodes are illegible. The scanner cannot decode them because of damage, distortion, or they’re simply too light to read. A good way to avoid getting an invalid barcode reading is to make sure you’re using a high-performance printer, as well as a ribbon and materials that are compatible with the printer. With Brady printing systems, the components (printer, ribbon, materials) actually “talk” to each other. The printer instantly recognizes the materials and ribbon, then automatically optimizes print settings.

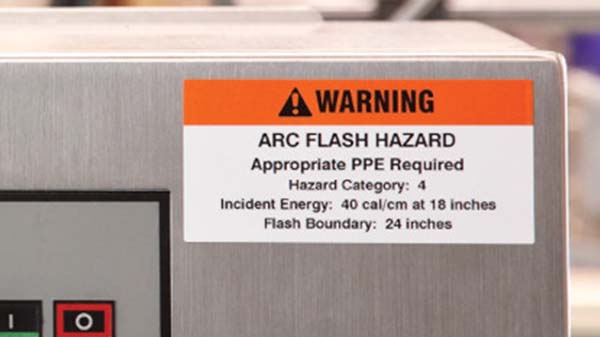

With all the different label materials available, you need to be sure your labels are suited for each barcode application and the conditions they will endure. Look for labels that are built to be readable and scannable in all conditions, like Brady labels. Popular barcode label materials include those that withstand high and low temperatures, harsh chemicals, tough washdowns and excessive humidity.

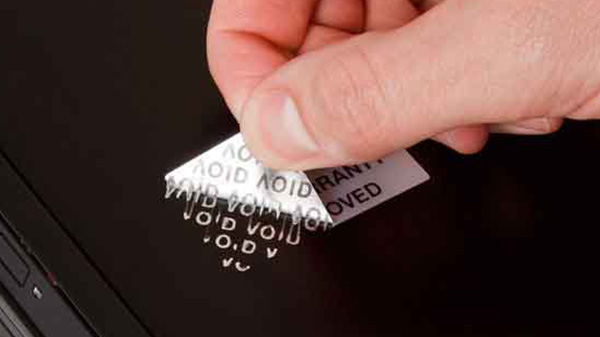

Tamper evident

Secure products against warranty fraud, product tampering and asset theft

Chemical/Solvent/Oil resistant

Get smear resistance, plus legibility in the harshest conditions

Heat resistant

Take on extreme heat with labels that withstand temps up to 500°F

Water resistant

Clean and sanitize with labels the endure washdowns and high pressure

Aggressive adhesive

Get 3x the adhesion on rough surfaces, extreme temps and harsh environments

PCB & Circuit Board

Ensure PCB and component ID can be tracked after solvents and wave soldering

Since barcodes need to be read, it’s important to create barcode images with clarity. Using high-performance printers will ensure labels are readable and trackable.

Ideal for printing crisp, clear barcode labels anytime, anywhere. Brady offers compact labelers that are fast, lightweight and durable. They can also share files, import spreadsheets and connect multiple users via Bluetooth.

For bigger barcode applications, consider using a benchtop printer. More stationary than handheld printers, benchtops offer high-quality barcode printing for industrial use. Brady benchtop printers specialize in higher volumes, high-mix jobs and precision printing.

Ask yourself: Where will the work happen? What conditions will it need to endure?

Since work environments are so diverse, printers need to be as well. Think about the controlled conditions in a clean room or lab. Then think about the unpredictable nature of on-site work. Extra-durable printers can withstand drops, shocks and even crushes.

Knowing this, Brady designed a printer for nearly every type of work environment. Some work well outdoors; others are great for labs, shops or offices. The ability to print on demand is a big factor for on-site work, as is connectivity. Ultimately, you should consider how you like to work. Here’s a Top 10 list of features you should consider:

Nearly every Brady label printer will print crisp, clear barcodes.

There are many different kinds of optical scanners and RFID readers. Two popular types are handheld and fixed (also known as hands-free). Though they have a few differences, both offer automated efficiency and are incredibly precise.

When choosing a barcode reader, look for one that fits the application. Consider which features you’ll need to make your scanning process smooth and efficient:

You may need different scanner technology depending on the application. If you have a direct line of sight to a barcode (meaning the scanner will read a barcode with an optical laser), you can use an optical scanner. However, if you plan on using RFID technology, the items you’re tracking will be sensed with radio frequency instead of a direct scan. This saves time as RFID tags can be “read” automatically once they get within a certain range.

Since there are so many different industrial applications, Brady offers both barcode scanners and RFID readers. Ruggedized for daily use, these dependable devices are quick, accurate and ready to handle all your data-collection needs

Yes. Barcode scanning software plays a big role in data automation. A scanner will read a barcode image and decode it, then forward it to a computer where users can interact with the data. The type of scanning software you choose should be:

With Brady scanning software, you get all three – plus extra features to maximize efficiency. Options include:

Ideal for automated, error-free labeling that practically manages itself. Fast and accurate, you can export .csv or .txt data label files, plus customize by combining templates.

This software lets you create labels quickly for smoother workflows. It simplifies the labeling process by automating data input through a barcode scanner, keyboard or custom script directly to a template.

This software lets you unlock all information about a product with a QR code. You can create a unique digital record (with product specs, manuals, videos, reordering and maintenance history) by linking it to a label. Talk to your Brady rep or contact us for more information.

Implementing new methods of identification can unlock more potential for your business. Barcode labeling gives you greater visibility into operations so you can:

Discover more ways you can connect it all – from the shop floor to the cloud – with Brady. We’ll custom-build an intelligent manufacturing solution to fit what’s next in your future.