Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

ANSI (American National Standards Institute) is an organization that develops and publishes standards related to systems, processes and products in the United States.

While highly regarded, ANSI standards are voluntary. Unlike OSHA, ANSI doesn’t legally enforce its standards, but instead, provides quality safety guidelines that produce efficient business procedures and high-quality products. That said, OSHA has largely adopted ANSI Z535 standards for safety signs. According to the ANSI website, the Institute represents approximately 270,000 organizations and 30 million individual professionals.

Some of the most well-known quality standards outlined by ANSI are the ANSI Z535 Safety Signage Standards based on the International ISO 3864. These standards, which address different elements of safety signage, are organized into six sections. Watch the video below for an overview of ANSI Z535, and then dive into the details.

Section 1 of the ANSI Z535 standard provides standards for color-coding safety signage. Similar to OSHA-adopted standards, it describes in detail what colors should be used for each type of safety signage, including:

| Red | for use with danger signs |

| Orange | for use with warning signs |

| Yellow | for use with caution signs |

| Blue | for use with notice signs and other non-safety related signs |

| Green | for use with first aid signs |

| Purple | for use with user-defined signs |

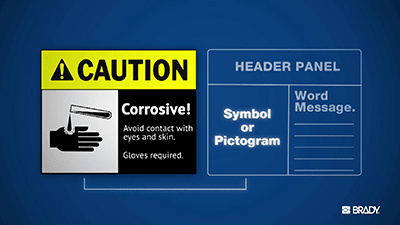

Section 2 outlines standards for uniformity within the layout of safety signs to provide visibility and legibility. Think sign size and shape, as well as symbols.

This consistency — the fact that someone will come to know a particular color or shape associated with a certain aspect of safety — improves the likelihood of being able to immediately recognize a safety sign, even if seen at a distance.

The section about visibility and legibility of safety signage also addresses the formatting of words used on the signage. Like the other standards outlined in this section, standards for word formatting are meant to clearly and immediately communicate the level of danger presented.

Following these standards:

|

“Danger” should be written in white lettering over a red background |

|

“Caution” should be written in black lettering over a yellow background |

|

“Warning” should be written in black lettering over an orange background |

|

“Notice” should be written in white lettering over a blue background |

When seconds count in an urgent situation, consistent formatting can mean the difference between a good outcome and a bad one.

Section 3 details safety symbols. Not to be understated, safety symbols can be more universally recognizable than wording. After all, you don’t have to translate symbols into various languages.

ANSI Z535 presents four major categories for safety symbols: hazard alerting, mandatory action, prohibition and informational.

Section 4 details safety signage standards. Here you’ll dig into the appropriate use of labels on individual products. For example, signage providing instructions for machine operation and machine equipment will be different depending on the type and location of the machine.

Not only will you learn about the label itself, you’ll also find details on label design and how to apply various labels. In situations of high heat or harsh environments, durability is key. As such, standards should also meet durability requirements. It's important to find the correct safety sign material so that your signs can withstand such environments. These labels may also be used to provide safety-related instructions for operators or repair workers who interact with the product.

From squaring off areas for clearing to blocking off a crime scene, barricade tape is essential in a variety of situations — hence its detailing in section 6 of ANSI safety and signage standards. Here, you’ll find barricade tape standards, as well as proper applications for using barricade tape. For example, if a staircase is damaged or chemicals are spilled, barricade tape may be used to advise employees of the danger.

This section also discusses best practices for labels and signage used in lockout / tagout procedures. Lockout / tagout labels are used to confirm that a machine is off and prevent it from being restarted without removing the label. Meanwhile, lockout / tagout signage advises that a lockout / tagout procedure should be observed.

To top it all off, section 6 outlines standards between collateral materials (think additional informational materials like product safety manuals) and safety signage.

According to this section, all additional information regarding safety signage presented in collateral materials should be consistent with the standards outlined in previous sections of ANSI Z535. This is meant to prevent conflicting outside information from tarnishing safety signage expectations.

Although many would assume these standards stay consistent, think otherwise. ANSI standards are updated every five years, so make sure you’re checking back periodically.

Suggested updates are either approved or denied by the ANSI Board of Standards Review. The most recent update occurred in 2017, and even brought about changes for color-coding in safety signage.

All of these standards can be used in a variety of industries: manufacturing, construction and food production, just to name a few. Take a look at how these standards work to prevent common emergencies like:

In addition, these standards are used for general purposes such as:

And there’s more — find other helpful materials

While ANSI Z535 standards are effective guidelines for safety, they can’t serve their purpose unless properly practiced. For example, if you do not have the right printing equipment available, you may not be able to produce safety signage that meets the ANSI Z535 specifications.

Color values may be inexact, signage may be formatted incorrectly or you may not be able to use durable labeling materials for your sign and label printer. To avoid this, workplaces must do their part, ensuring the proper equipment and materials to fully meet these standards.

Create a safer, more efficient workplace through visuals.

Learn More

What are OSHA's requirements related to ANSI Pipe Marking Standards?

Learn More

Understand the types, requirements and use for workplace safety signs and symbols.

Learn More