Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanner and Printer Kits

Barcode Scanner and Printer Kits

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Brady Safety Lockout Tagout Services

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

When you’re a compliance manager or part of a safety crew, you know how critical it is to take the necessary precautions during the transportation of hazardous chemicals. It’s key to avoiding accidents and putting safety first. And it’s why you and your team must know precisely how to go about chemical handling and regulatory compliance to stay safe.

Hazardous materials need to be clearly labeled to notify workers of the potential dangers of the chemicals they deal with. But additional critical information means an even safer workplace where your team has the best chance of going home safe and sound at the end of the day. Make on-demand labels with a GHS label printer to ensure you are always up to date with GHS Label Requirements.

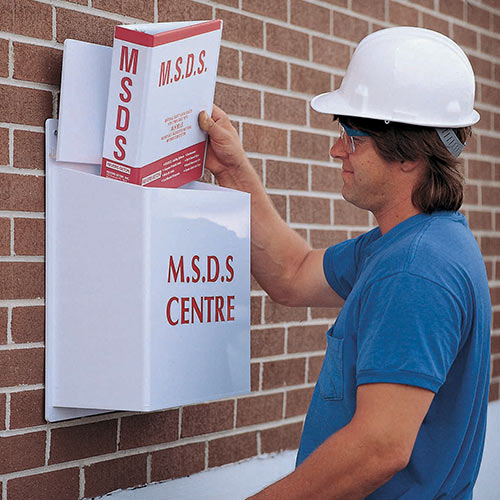

It used to be that this important safety information was provided via a Material Safety Data Sheet, or MSDS. The MSDS provided information on the potential health and safety hazards of a particular chemical. Useful information, for certain, but an updated document, called a Safety Data Sheet (SDS), became the new standard you can rely on — and continue to rely on — for even more instruction for a safer workplace.

We’ll spell out the details and differences between the SDS and MSDS, but first, a little background.

OSHA's Hazard Communication Standard (HCS), also known as HazCom, ensures that companies provide hazardous chemical handling information to employees. Written in the early 1990s, the standard required chemical suppliers to provide an MSDS with this important information.

In 2012, OSHA revised their HazCom standards, the intent being to increase workplace safety and make it easier for workplaces to properly use, store and dispose of chemicals. The new standard — the SDS, which officially replaced the MSDS — saw many improvements in consistency and format and is the ongoing standard for health and safety information on hazardous chemicals.

Simply put, the Safety Data Sheet is a simpler, more consistent and more effective way to communicate the hazards of chemicals. Because of the lack of standardization and continuity in Material Safety Data Sheets, it became challenging to find and correct errors because of the varied structure, format and detail. Luckily, standardizing the data across the globe resolved this issue — and helped match the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS). GHS training materials are a great resource for organizations to familiarize workers with these guidelines. These positive changes all contribute to making it easier for employees to follow the guidelines. Stay updated with the GHS Labeling Requirements. After all, the lives of your crew are at stake.

When hazardous materials aren't labeled correctly, workers are exposed to several hazards. Incorrect or incomplete labels can lead to employees mishandling chemicals, which can unfortunately result in severe injury or even death. According to the Bureau of Labor and Statistics, in 2020, there were 4,764 fatal work injuries recorded in the United States — that means a worker died every 111 minutes from a work-related injury.

With time and experience, we acquire more knowledge — and things evolve. It’s no different with the Safety Data Sheet replacing the MSDS. We know more now. And have the opportunity to share it for the sake of crew safety.

If you’ve been accustomed to seeing an MSDS, it’s helpful to understand the differences and updates that an SDS provides, so you can adapt and adopt with confidence. Let’s look at a few examples:

Reference this handy chart to see how the MSDS evolved into the more consistent and easy-to-understand standards found in the Safety Data Sheet:

| Material Safety Data Sheet (MSDS) | Safety Data Sheet (SDS) | |

| Identity of the chemical | ||

| Physical and chemical properties of the chemical (flammability and explosive properties) | ||

| Health hazards of the chemical | ||

| First-aid measures for exposure to the chemical | ||

| Fire-fighting procedures for the chemical | ||

| Protective measures for handling and using the chemical | ||

| Hazard statement | ||

| Signal word | ||

| Pictograms | ||

| Ingredients and percentages of mixed chemicals |

A Material Safety Data Sheet (MSDS) is a document, normally many pages long, that travels with or ahead of hazardous chemical shipments, warning users of the specific dangers of such products and guidance on their safe handling, storage and disposal. While an MSDS was a helpful document that carried key safety information, it lacked consistency in format and details, making it sometimes difficult to follow.

An SDS goes beyond the information in an MSDS, addressing a specific chemical's identification, potential hazards and several more points of information.

As illustrated, the SDS provides more information and standardizes safety for all industries. This means that all workers — no matter what company they work for — will be given an SDS that contains the same information. Additionally, an SDS must now include a section on environmental hazards, which the MSDS did not cover.

While both documents contain important health and safety information, it is essential to understand that they are not the same document. If you are working with a hazardous chemical, be sure to familiarize yourself with the SDS, as it is now the standard for safety.

Standardizing the SDS also brought about the standardization of GHS label requirements — all GHS labels must now include the words "danger" or "warning.” These easy-to-understand words inform employees of the potential hazards when working with or around the hazardous material in question. They also provide essential information about what steps should be taken in the event of exposure.

Before the change to the SDS as the standard for chemical safety information, these words could have meant different things on a datasheet depending on the chemical supplier — causing confusion for employees trying to understand what they're working with and how it should be handled.

Now, all employees can know that "danger" indicates that a chemical is more hazardous than one that has a "warning" label. These universal definitions make it easier for employees to understand what they're dealing with when handling hazardous materials in the workplace.

There are 16 sections of a GHS-formatted SDS sheet. Much of the information comes in the form of signs, pictograms and labels. These 16 points of information let workers know the following:

When digging in to understand the differences between these two important documents, one word describes what’s happened … evolution. While the MSDS certainly carried important information and provided safety guidelines for handling dangerous chemicals, it did so with a lack of consistency and standardization. In the years that have transpired since the MSDS was the go-to document, we’ve learned a lot. And the Safety Data Sheet is a reflection of that learning, requiring the addition of more detailed information about a chemical, as well as a format that works across the board, ensuring that everyone gets the same information. And consistent, standardized information is the key to keeping your crew as safe as possible when handling dangerous chemicals.

Look to the Safety Data Sheet as your go-to document that makes it as easy as possible to follow the guidelines and send everyone home safely at the end of the day.

As workplace hazard communication evolves, you need to keep up to date to ensure safety.

Learn More

Understand the hazardous waste label requirements to comply with EPA/RCRA regulations.

Learn More